Click to call us on:

01494 534364

Isotemp (Heating and Ventilating) Ltd. Services

Site surveys are all part of the package we provide and are included in any costs we give for the supply and installation of ductwork.

Please call us for a fast. accurate and competitive quote.

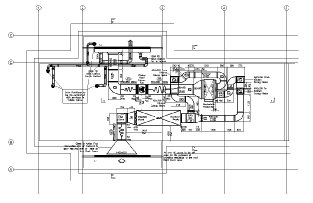

Design / CAD / Estimating

We employ 3 dedicated CAD design engineers who are tightly integrated into the project teams from the start.

Operating the renowned and industry preferred AutoCAD MEP system we design within an integrated environment which allows us to produce bills of materials, provide 3D isometrics for clients, produce working drawings for the fitters as well as send component CAD/CAM files straight to our CNC sheetmetal section.

Sheeetmetal Duct Fabrication

Our dedicated facility in Loudwater is equipped with a CNC plasma cutting machine for the manufacture of complex sheet metal profiles as well as a duct forming coil line for the automated production of straight sections. Combined with a streamlined workshop and a skilled workforce we are able to provide a high quality product quickly and efficiently.

Ductwork Installation

We offer a full ductwork installation service. Our fully trained installation engineers are provided with all the tools and equipment necessary to carry out the job and are fully trained in all relevant health and safety issues.

We operate to the high standards required by hospitals and clean rooms. All ductwork is made and installed in accordance with the BESA specifications DW/144. Cleanliness of ductwork is determined by BESA Guide TM2. Pressure testing of ductwork is carried out as required upto 2000pa. All members of staff know the standards we expect and work to achieve this.

Health & Safety

Isotemp is committed to Health & Safety. We have been been CHAS approved since 2016 and are approved by BESA as part of their assessment program..

All our fitters undergo continuous training and assessment and are SKILLCard registered. SKILLcards enhance awareness of health & Safety issues as well as allowing the holders the opportunity to develop existing skills. We are also compliant with all COSHH regulations.